Bearing maintenance and judgment

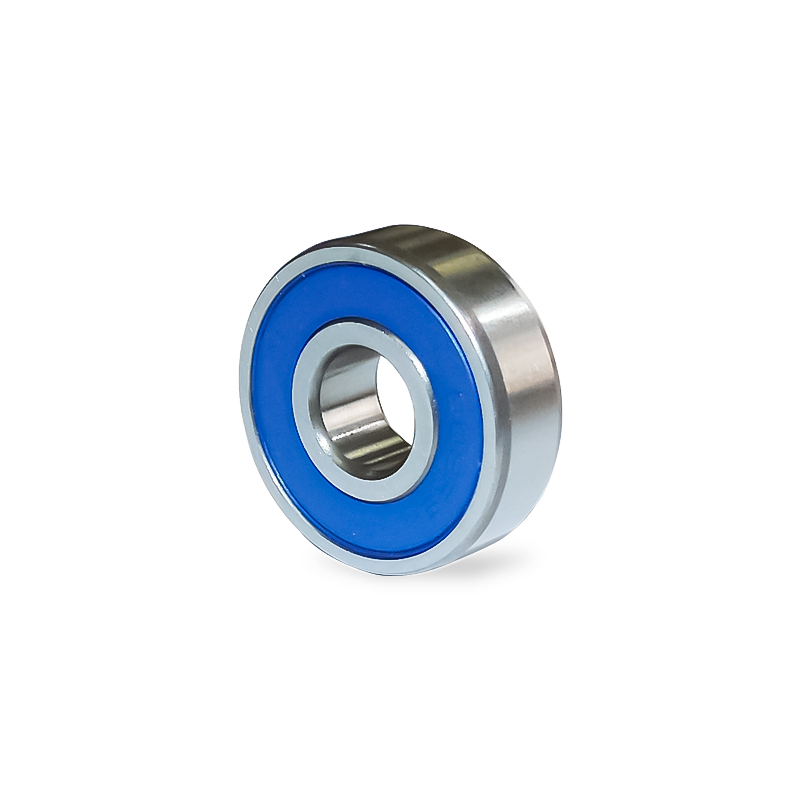

When determining whether the disassembled bearing can be reused, clean and inspect the bearing, carefully inspect the surface of the raceway, rolling surface, mating surface, retainer wear, increase in bearing clearance, and decrease in dimensional accuracy. Damaged, abnormal. For non separable ball bearings, use a single handed flat end inner ring and rotate the outer ring to check for smoothness. The rolling elements of individual bearings such as tapered roller bearings and the rolling surface of the outer ring can be inspected separately. Large bearings cannot be rotated by hand. Pay attention to the appearance of rolling elements, raceways, cages, ribs, etc. The higher the importance of bearings, the more careful the inspection required.

When determining whether the bearing can be reused, it should be determined based on the degree of damage, mechanical performance, importance, working conditions, inspection time, and other relevant factors of the bearing. However, if the following defects are found during the inspection process, the bearing cannot be used anymore and needs to be replaced with a new one.

1. There are cracks or gaps in any of the inner ring, outer ring, rolling element, and cage.

2. Either of the ferrules or rolling elements is broken.

3. There are obvious scratches on the rolling surface, ribs, and rolling elements.

4. The cage is significantly worn or the rivets are noticeably loose. Rust or scratches on the surface of the raceway and the rolling element. There are severe dents or bruises on the surface of the raceway and rolling elements. There is significant creep on the inner diameter surface of the inner ring or the outer diameter surface of the outer ring, resulting in significant discoloration due to overheating.

5. Bearings, sealing rings, or dust covers sealed with grease are severely damaged.

When determining whether the bearing can be reused, it should be determined based on the degree of damage, mechanical performance, importance, working conditions, inspection time, and other relevant factors of the bearing. However, if the following defects are found during the inspection process, the bearing cannot be used anymore and needs to be replaced with a new one.

1. There are cracks or gaps in any of the inner ring, outer ring, rolling element, and cage.

2. Either of the ferrules or rolling elements is broken.

3. There are obvious scratches on the rolling surface, ribs, and rolling elements.

4. The cage is significantly worn or the rivets are noticeably loose. Rust or scratches on the surface of the raceway and the rolling element. There are severe dents or bruises on the surface of the raceway and rolling elements. There is significant creep on the inner diameter surface of the inner ring or the outer diameter surface of the outer ring, resulting in significant discoloration due to overheating.

5. Bearings, sealing rings, or dust covers sealed with grease are severely damaged.