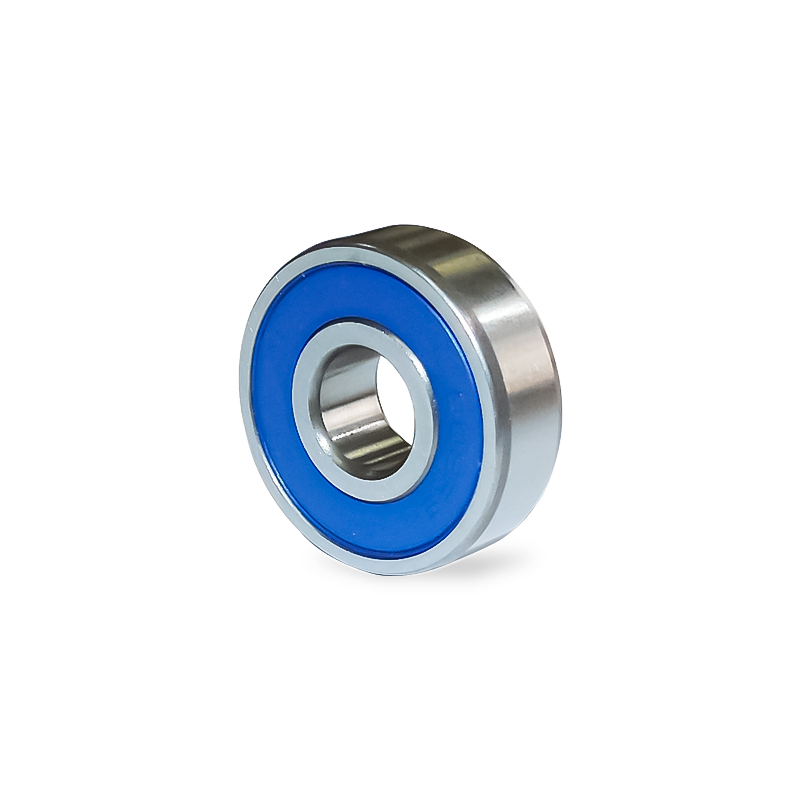

Method for Regularly Checking the Failure of Outer Spherical Bearings

After the motion cycle, oscillation and noise remain at a certain level, and the spectrum is very pure, displaying only one or two times the frequency. After the outer spherical bearing is put into operation, the vibration and noise of the bearing begin to increase. Sometimes abnormal sounds are emitted, but the oscillation increases rapidly. At this point, the bearing kurtosis suddenly reaches a certain value. The bearings exhibit late stage fault characteristics to indicate severe faults (normal surface bearing damage, such as shaft, combustion, sand cracking, raceway, ball wear, etc.) for no more than one week, and the equipment volume is larger, the speed is faster, and the interval is shorter. Firstly, we must say that keeping the bearing lubricant clean and very tight.

Bearings exhibit strong regularity and repeatability in their applications. Rare * will display a frequency spectrum three times higher than the power frequency, and the bearing condition is very stable and has entered a stable working cycle. Attention: The oil should be filtered before use. It is possible to gather oil with remaining pollutants and then empty the oil. However, please note that bearings are not suitable for adding too much grease. Due to the potential for these residual fibers to wedge between bones and cause damage, it is particularly important to pay attention to this issue in the application of small bearings. Therefore, before inspecting the outer spherical bearing, the outer surface of the bearing should be cleaned first, and then the parts around the bearing should be disassembled. Everyone should be aware that oil seals are a very weak part, as special caution should be exercised during inspection and disassembly to avoid excessive force and damage to the parts. Lubricating oil is very sealed, not only used for surface bearings of outer balls, but also for all imported bearings. Then carefully inspect the oil seals of the bearings and surrounding parts. If adverse symptoms have already appeared, they must be easily changed. Poor oil seals will cause bearing damage, and the bearing cloud will become abnormal and the facility will be shut down. We feel that the surface load of the outer ball is indicated as a fault at the beginning of the cycle. When using new engine oil to lubricate the surface bearing of the outer ball, the new engine oil should be refilled. If the old engine oil is discharged, it should be rotated at low speed for a few minutes. Apply a little lubricating oil between two fingers. If there are pollutants, they can be felt. Alternatively, apply a thin layer of lubricating oil to the other side of the palm and seal the lamp. Therefore, in actual bearing fault diagnosis, once late fault features are detected, bearing faults should be judged without hesitation and efforts should be made to accelerate the speed of resettlement inspection and maintenance.

When activating surface bearings with ordinary high-quality outer balls, the vibration and noise are relatively small, but the spectrum is somewhat scattered and the amplitude is small, which may be caused by a lack of manufacturing processes (such as external). Burrs. When modifying bearings that use grease lubricants to be easy to lubricate, the cutting tool used should prevent cotton cloth from adhering to any part of the bearing. Secondly, we also need to check the lubricating oil of the bearings.

Bearings exhibit strong regularity and repeatability in their applications. Rare * will display a frequency spectrum three times higher than the power frequency, and the bearing condition is very stable and has entered a stable working cycle. Attention: The oil should be filtered before use. It is possible to gather oil with remaining pollutants and then empty the oil. However, please note that bearings are not suitable for adding too much grease. Due to the potential for these residual fibers to wedge between bones and cause damage, it is particularly important to pay attention to this issue in the application of small bearings. Therefore, before inspecting the outer spherical bearing, the outer surface of the bearing should be cleaned first, and then the parts around the bearing should be disassembled. Everyone should be aware that oil seals are a very weak part, as special caution should be exercised during inspection and disassembly to avoid excessive force and damage to the parts. Lubricating oil is very sealed, not only used for surface bearings of outer balls, but also for all imported bearings. Then carefully inspect the oil seals of the bearings and surrounding parts. If adverse symptoms have already appeared, they must be easily changed. Poor oil seals will cause bearing damage, and the bearing cloud will become abnormal and the facility will be shut down. We feel that the surface load of the outer ball is indicated as a fault at the beginning of the cycle. When using new engine oil to lubricate the surface bearing of the outer ball, the new engine oil should be refilled. If the old engine oil is discharged, it should be rotated at low speed for a few minutes. Apply a little lubricating oil between two fingers. If there are pollutants, they can be felt. Alternatively, apply a thin layer of lubricating oil to the other side of the palm and seal the lamp. Therefore, in actual bearing fault diagnosis, once late fault features are detected, bearing faults should be judged without hesitation and efforts should be made to accelerate the speed of resettlement inspection and maintenance.

When activating surface bearings with ordinary high-quality outer balls, the vibration and noise are relatively small, but the spectrum is somewhat scattered and the amplitude is small, which may be caused by a lack of manufacturing processes (such as external). Burrs. When modifying bearings that use grease lubricants to be easy to lubricate, the cutting tool used should prevent cotton cloth from adhering to any part of the bearing. Secondly, we also need to check the lubricating oil of the bearings.